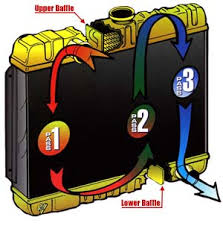

Many companies offer radiators configured as a double-pass or triple-pass design and the name can be a little misleading. On the surface, a double-pass radiator sounds like the fluid goes through the radiator two times and that is not the case.

A double-pass design is nothing more than a baffle welded inside the end tank. What this does is cut the radiator in half, and the fluid flows through each half in series. Since each section is half the size of a full core, the fluid velocity is twice as fast and the pressure drop is now doubled. Many will argue this design is superior because the fluid stays in the radiator longer. The reality is that the fluid has twice as far to go but it is also traveling twice as fast. In the end, the fluid flows through each tube only one time and a more appropriate description would be a U-flow. The design demands both inlet and outlet to be on the same tank.

A triple-pass has two baffles, one in each end tank. Now the core is divided into three small sections and flows through each one in series. This creates very high flow rates and high pressure drops though the system.

Feel free to post your comments by filling out the form below. If you have any questions that require a reply click here. Note that questions posted in the comment form will NOT be replied too.